Stabilized Decomposed Granite & Crushed Stone Pathway Mix

A Naturally Beautiful and Durable Pathway Solution

Our Stabilized Pathway Mix consists of decomposed granite or crushed stone screenings pre-blended with Organic-Lock™, an organic stabilizing binder. This binds and locks the pathway mix to provide a durable, permeable and natural aggregate surface. These stabilized decomposed granite surfaces substantially resist the erosive effects of weather and traffic compared to traditional gravel pathway materials.

With a natural look much less obtrusive than concrete or asphalt, Kafka’s Stabilized Pathway Mix blends in well in natural settings, making it popular for use in botanical gardens, green roofs, nature paths, greenways, golf course cart paths, trails or any environment where a more organic feel is desired.

How Does it Work?

Kafka Granite’s Stabilized Pathway Mix aggregate is 1/4″ minus, with fines pre-blended with Organic-Lock™. This specific gradation allows the product to compact well, and water is absorbed by the Organic-Lock™ binder. The binder swells in size and grips onto surrounding aggregate particles, holding them together to create enhanced stability and significantly reducing erosion.

Once the gel forms to its maximum swell volume, it is unable to take on any new water, and the excess water passes directly through the system down into the groundwater table. Over time, the gel releases its water through evaporation into the atmosphere and through percolation into the groundwater table, recharging the system to be ready for the next rainfall.

If you are considering using decomposed granite or crushed stone screenings for areas with a very steep grade or prone to excessive erosion, Kafka’s Wax-Coated Aggregate may be more suitable for your project requirements.

Get a QuoteADVANTAGES

Kafka’s Stabilized Pathway Mix is available in nearly 40 different colors, allowing landscape architects and designers greater creativity in their projects. Whether matching our Pathway Materials to other products or creating contrasting color spaces in your design, Kafka has you covered.

Another advantage of working with Kafka is the ability to source your entire project from complementary categories of our natural stone products.

How to Install Kafka Granite’s Stabilized Pathway Mix

Kafka Granite’s Stabilized Pathway Mix is a sustainable, natural-looking alternative to traditional paving. Made from 100% natural materials, it’s water-permeable, wheelchair accessible, and available in dozens of colors. Watch this video to learn how to install a durable, long-lasting pathway.

Installation & Maintenance

Proper installation and maintenance is critical to the durability and longevity of any pathway, and that all starts with a plan. First, you should decide where you want your path to be. You can do this simply by drawing a crude sketch of your vision and pathway location or even by staking out the path along your intended route. Next, you will need to determine how much material is necessary for the project. This is dependent upon a number of factors, including the size of your path, the materials being used for the aggregate and the intended use of the pathway (pedestrian or vehicular).

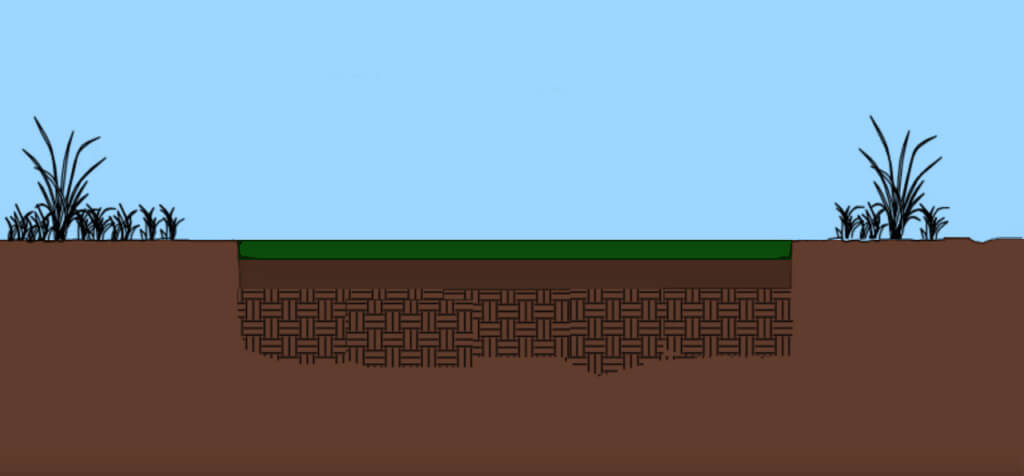

Excavate & Prepare

The depth of your base material and Kafka’s Stabilized Pathway Mix is determined by the pathway’s intended use. Your base should utilize 4-6 inches of compacted local DOT-approved road base for pedestrian traffic and 8-12 inches of compacted base material for vehicular traffic. Kafka Granite recommends a minimum 3 inches of compacted Stabilized Pathway Mix for pedestrian pathways and 4 inches for vehicular use. Use the Pathway Mix Calculator to determine the amount of material to order.

Hydrate & “Snowball Test”

Kafka’s Stabilized Pathway Mix is pre-blended with Organic-Lock™, which will need to have a moisture content of 8-10% for installation. Start by picking up a handful of the pathway material and attempting to make a snowball. This material should fall apart in your hand either on its own or after a gentle prodding. If the material holds its form already, no further water is needed. If the snowball holds its form and has a wet sheen to it, the material is too wet and you must add more dry material or spread it out and let the material dry.

Too Dry

Ideal Moisture

Too Wet

Spread & Compact

Using an asphalt/paver installer is the most efficient and effective means of spreading the properly hydrated material, as it provides a consistent depth of placement. Hand raking can be used in areas where it is no possible to use an asphalt/paver installer. In these situations, it’s important to keep a strong focus on depth consistency across the installation. Be sure to compensate for the expected depth of compaction when finalizing the end depth. It is also important to account for crowning or grading slope to eliminate any areas for rainwater to accumulate and pool.

Compact material with a 1-2 ton non-vibrating drum roller until visible lines are eliminated. Hand tamp any hard to reach areas. Note that the Kafka Stabilized Pathway should be firm, but loose aggregate will appear on the surface as time passes for a natural look and feel.

If the loose material on the surface is excessive, water the surface, scarify the affected area, and re-compact as needed. Additional material can be spread and compacted as needed.

Frequently Asked Questions

Kafka’s Stabilized Pathway Mix creates natural granite aggregate surfaces, and using them in your construction or design project could gain your points toward LEED (Leadership in Energy & Environmental Design) certification.

Our decomposed granite is a naturally produced material and is less obtrusive than asphalt and cement, and our stabilizing binder is 100% organic. It is a “green” pathway solution, which will aid the natural soil and water flow when installed.

Recycled materials such as porcelain and slag are available to aid in a more environmentally friendly design. Furthermore, many of our natural aggregates are also sourced locally, which may aid in regional priority credits.

Standard Pathway Mix is ideal for low-traffic areas that call for a permeable and easy-to-manage pathway solution. This option doesn’t include any additives, but is crushed to the perfect size to warrant optimum compaction and drainage.

Stabilized Pathway Mix includes our aggregate mixed with Organic-Lock™, an organic stabilizing binder. The addition of an organic binder enhances the durability of these pathways while not compromising its natural quality. These pathways remain permeable and work well in areas with slightly higher pedestrian or vehicular traffic, or in areas that require wheelchair accessibility.

Wax-Coated Aggregate is the most durable pathway material offered by Kafka. Our crushed stone, granite aggregate or recycled material comes premixed with an engineered polymer that completely eliminates mud and dust and is rated for higher traffic than the Standard or Stabilized Pathway Mixes. The addition of engineered polymer makes this an impermeable pathway, but this is the ideal solution for areas that are steeply graded.

The product is commonly shipped via bulk end-dump trucks and trailers, with an average truckload of material weighing approximately 23 tons — though the type of material and the size of the truck and trailer will cause this to fluctuate slightly. Less-than-truckload quantities are available in one ton increments, but may be subject to additional set-up fees due to small production runs.

If bulk truckload shipping is not an option, our Pathway Mixes can be packaged in ~3,000-pound super sacks. These 1½-ton bags provide easy transportation via flatbed, van, or LTL common carriers, and also facilitate easier storage and handling on job sites. Optional rain covers are also available. Specialty aggregates that are packaged in super sacks are available in 1 ton minimum orders and may be subject to set-up fees.

Yes, our decomposed granite is a naturally produced material and our stabilizing binder is 100% organic. It is a “green” pathway option that aids the natural soil and water flow when installed.

Recycled materials such as porcelain and slag are also available to contribute to more environmentally friendly design. In addition, many of our natural aggregates are sourced locally, which may aid in regional priority credits.

A stabilized pathway provides a durable, permeable and natural aggregate surface. Compared with traditional aggregate materials, our stabilized pathways better resist the erosive effects of weather and foot or vehicle traffic, while retaining environmentally-friendly qualities and natural aesthetics.

Kafka’s Stabilized Pathway Mix can be used nearly anywhere, but its natural granite look is appealing for those who want to add it to more natural-looking, rustic environments.

These paths work well in and complement green spaces — botanical gardens, green roofs, nature paths, greenways, golf course cart paths, trails and any space where you want to create a natural, organic feel and environment. However, these paths have also become a popular choice for corporate walking paths, outdoor malls, public courtyards and patios.

Stabilized decomposed granite pathways aren’t entirely maintenance-free, however, regular upkeep will extend their lifespans and will keep them looking fresh — unlike cracked concrete, crumbled asphalt or uneven pavers.

Maintaining stabilized pathways is a fairly simple procedure. For minor repairs, pathways can be re-wet and rolled anytime. Kafka always recommends investing in an auxiliary super sack of material in case the need for more involved repairs arises. If bigger repairs are needed, slightly scarify the top layer of the damaged area. Then activate (moisten) the new pathway mix, spread the material and compact the area with a 1-ton roller to level.

After the repaired area has cured, it should look and feel like the surrounding pathway.